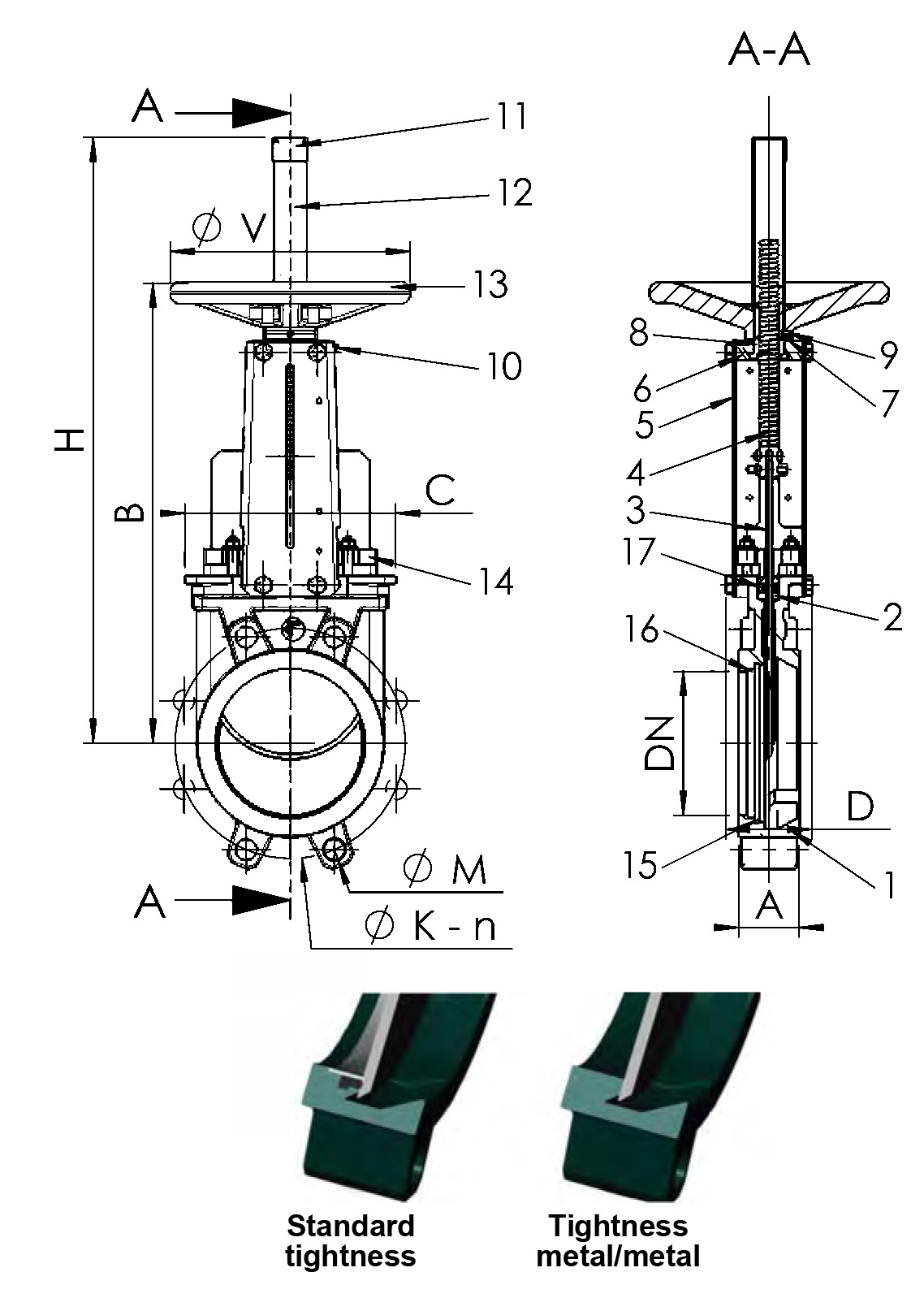

KNIFE GATE VALVE CAST IRON VG3400-00 RISING STEM DIN PN 10

Material:

cast iron EN-JL1040Dimensions:

DN 50 - 600DESCRIPTIONS

Range : from DN 50 to DN 600.

Function ON/OFF or regulation.

Wafer threaded mounting ISO PN10.

Unidirectional tightness, direction indication thanks to the arrow on the body.

Small retention zone: the gate is guided in the body and has little clearance.

Gland assembly: packing and O-ring (same materials as seat joint) to assure

the elasticity and decrease the operating torque. Small head loss. Possibility

to regulate thick fluids with the adaptation of a diaphragm ring.

MEDIA

· General use : Pulp production, water, water treatment, waste water, chemical industry ( powdery or crystallizing products), wine-producing, pulverized products (cement work, pneumatic transport, stocking).

OPTIONS

Others materials on request (If marked) Maximum temperature

Materials

| No. | Parts | Material |

|---|---|---|

| 17 | O-Ring | Nitril |

| 16** | Support ring | Stainless steel 316 |

| 15** | Gasket | Nitril |

| 14 | Packing gland | Aluminium (DN 50-450) Steel (DN 500-600) |

| 13 | Handwheel | Cast iron EN-GJL-250 |

| 12 | Protection tube | Steel |

| 11 | Cap | Plastic |

| 10 | Greaser | Stainless steel |

| 9 | Stop screw | Stainless steel |

| 8 | Nut | Bronze |

| 7 | Friction washer | Bronze |

| 6 | Nut support | Zinc steel |

| 5* | Support plate | Steel + epoxy |

| 4 | Stem | Stainless steel 13%Cr |

| 3 | Gate | Stainless steel X5CrNi 18-10 |

| 2 | Packing | PTFE |

| 1 | Body | Cast iron EN-GJL-250 |

| * Pre-shaped parts up to DN 300. | ||

| ** Missing parts on metal / metal tightness. |

Characteristics

Dimensions

| DN | A | B | C | D | Ø V | H | Ø K | n | Ø M | Weight (kg) | |

|---|---|---|---|---|---|---|---|---|---|---|---|

| mm | inch | ||||||||||

| 50 | 2" | 40 | 283 | 124 | 83 | 200 | 348 | 125 | 4 | 4 x M16 | 7,5 |

| 65 | 2"1 /2 | 40 | 308 | 139 | 83 | 200 | 388 | 145 | 4 | 4 x M16 | 9,0 |

| 80 | 3" | 50 | 333 | 154 | 83 | 200 | 413 | 160 | 8 | 4 x M16 | 10,0 |

| 100 | 4" | 50 | 378 | 174 | 83 | 200 | 488 | 180 | 8 | 4 x M16 | 1 1,5 |

| 125 | 5" | 50 | 423 | 189 | 93 | 250 | 564 | 210 | 8 | 4 x M16 | 15,5 |

| 150 | 6" | 60 | 474 | 220 | 93 | 250 | 635 | 240 | 8 | 4 x M20 | 18,5 |

| 200 | 8" | 60 | 593 | 275 | 108 | 310 | 809 | 295 | 8 | 4 x M20 | 35,0 |

| 250 | 10" | 70 | 685 | 326 | 108 | 310 | 946 | 350 | 12 | 8 x M20 | 47,0 |

| 300 | 12" | 70 | 792 | 380 | 108 | 310 | 1118 | 400 | 12 | 8 x M20 | 61,0 |

| 350 | 14" | 96 | 900 | 438 | 290 | 500 | 1282 | 460 | 16 | 10 x M 20 | 117 |

| 400 | 16" | 100 | 978 | 494 | 290 | 500 | 1441 | 515 | 16 | 10 x M 24 | 151 |

| 450 | 18" | 106 | 1105 | 547 | 290 | 500 | 1587 | 565 | 20 | 14 x M 24 | 187 |

| 500 | 20" | 1 10 | 1215 | 613 | 290 | 500 | 1809 | 620 | 20 | 14 x M 24 | 205 |

| 600 | 24" | 1 10 | 1418 | 716 | 290 | 500 | 2060 | 725 | 20 | 14 x M 27 | 292 |