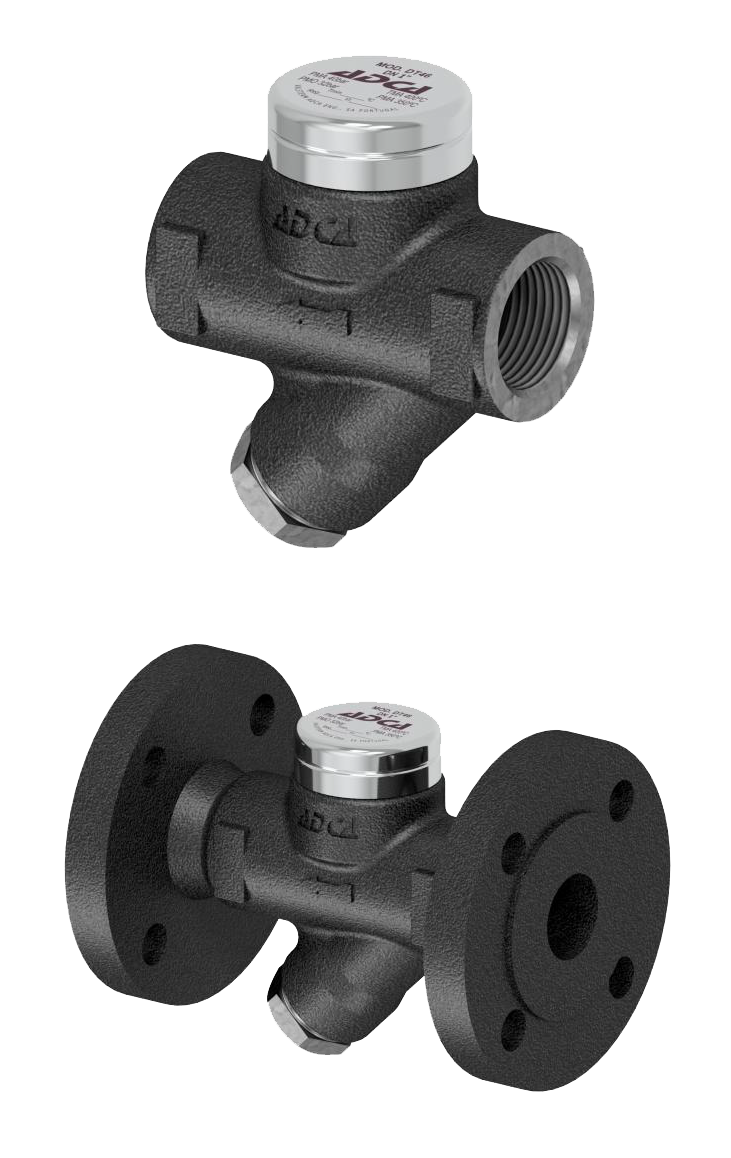

THERMODYNAMIC STEAM TRAP SCREW ENDS / FLANGED ADCA DT 46

Material:

cast steel 1.0460Dimensions:

1/2" - 1" / DN 15 - 25TECHNICAL DESCRIPTION

ADCA DT 46 thermodynamic steam traps are compact and easy to install and are excellent for embedding in high-pressure systems, including "Stream tracing" applications. The insulating coating provides consistent work and makes them practical for those applications where climatic conditions such as rain and wind affect their normal operation. The steam traps of this type have only one movable element and are used in a wide range of working pressure without additional adjustment. Connection could be thread or flange.

OPERATION

Discharge with interruption. Standard insulating coating. Saturated and superheated steam. The seat and valve have the option of replacing them without removing the condensate separator. It is not affected by hydraulic shocks and vibrations in the system. Built-in filter is easy to service.

WORKING FLUIDS / MEDIA

• Steam - saturated and superheated.

OPTIONS:

• Purge valve.

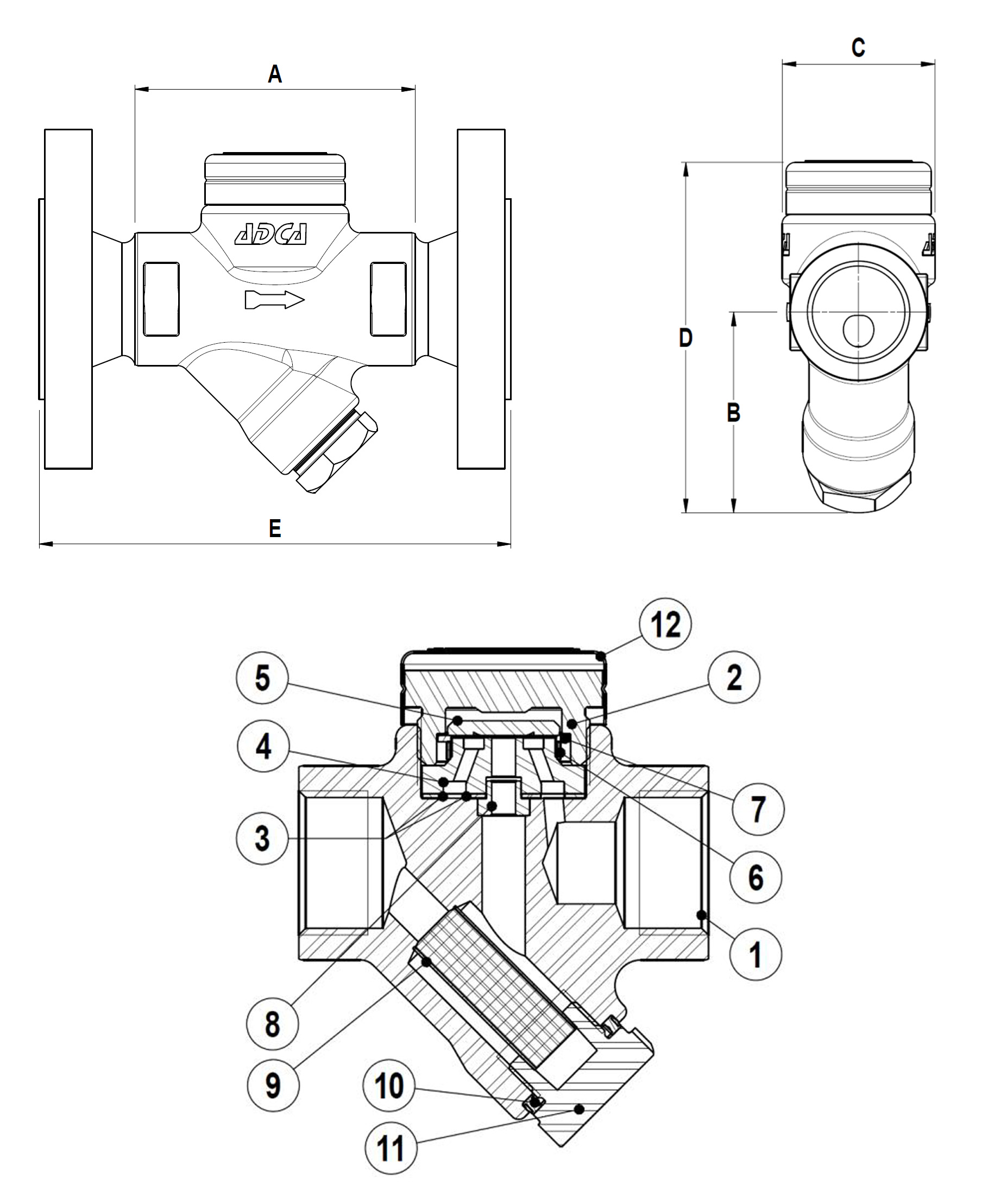

Materials

| No. | POSITION | MATERIALS |

|---|---|---|

| 1 | Body | P250GH / 1.0460 |

| 2 | Cover | AISI 304 / 1.4301; AISI 303 / 1.4305 |

| 3 | Gasket | stainless steel / graphite |

| 4 | Seat | hardened stainless steel |

| 5 | Valve | hardened stainless steel |

| 8 | Bush | AISI 304 / 1.4301 |

| 9 | Strainer screen | AISI 304 / 1.4301 |

| 10 | Gasket | stainless steel / graphite |

| 11 | Plug | A105 / 1.0432 |

| 12 | Insolating coating | AISI 304 / 1.4301 |

Characteristics

| SPECIFICATION | |

|---|---|

| Standard | DIN |

| Connection | threaded BSP / flanged |

| Cover connection | threaded |

| Construction | straight |

| Operation | automatic |

| Air release | automatic |

| Mounting | horizontal |

Dimensions

| Threaded or butt welded | FLANGED EN PN 16 / PN 40 | FLANGED EN PN 63 | FLANGED ANSI 150 | FLANGED ANSI 300 | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| DN | A | B | C | D | kg | E | kg | E | kg | E | kg | E | kg |

| 15 - 1/2" | 95 | 60 | 50 | 109 | 1,3 | 150 | 2,8 | 150 | 3,7 | 150 | 3,9 | 150 | 4,9 |

| 20 - 3/4" | 95 | 60 | 50 | 109 | 1,2 | 150 | 3,3 | 150 | 5,2 | 150 | 4,8 | 150 | 7 |

| 25 - 1" | 95 | 66 | 50 | 115 | 1,5 | 160 | 4,1 | 160 | 6,7 | 160 | 6,5 | 160 | 8,5 |

Flowrate

| FLOW RATE (kg/h) | |||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| МОДЕЛ | DN | DIFFERENTIAL PRESSURE (bar) | |||||||||||||

| 1,5 | 3 | 5 | 7 | 9 | 12 | 15 | 18 | 21 | 24 | 30 | 35 | 42 | 46 | ||

| DT 46 (hot) | DN 15 - DN 25 | 70 | 100 | 130 | 175 | 190 | 200 | 225 | 240 | 250 | 270 | 290 | 300 | 310 | 320 |

| 1/2" - 1" | 70 | 100 | 130 | 175 | 190 | 200 | 225 | 240 | 250 | 270 | 290 | 300 | 310 | 320 | |

| DT 46 (cold) | DN 15 - DN 25" | 170 | 230 | 300 | 335 | 390 | 435 | 485 | 520 | 575 | 600 | 645 | 695 | 740 | 800 |

| 1/2" - 1" | 170 | 230 | 300 | 335 | 390 | 435 | 485 | 520 | 575 | 600 | 645 | 695 | 740 | 800 |

Limits

| MAX WORKING PARAMETERS | |||||

|---|---|---|---|---|---|

| Max. working pressure / Bars | Т max. [°C] | ||||

|

FLANGED PN 40 / ANSI 300 |

FLANGED ANSI #150 |

FLANGED PN 63 |

FLANGED PN 100 |

FLANGED ANSI #600 |

|

| 40 bar | 19,3 bar | 63 bar | 100 bar | 90,5 bar | 50 °C |

| 37,1 bar | 17,7 bar | 58,5 bar | 92,8 bar | 80,2 bar | 100 °C |

| 33,3 bar | 14 bar | 52,5 bar | 83,3 bar | 72 bar | 200 °C |

| 27,6 bar | 10,2 bar | 43,5 bar | 69 bar | 59,7 bar | 300 °C |

| 23,8 bar | 6,5 bar | 37,5 bar | 59,5 bar | 51,4 bar | 400 °C |