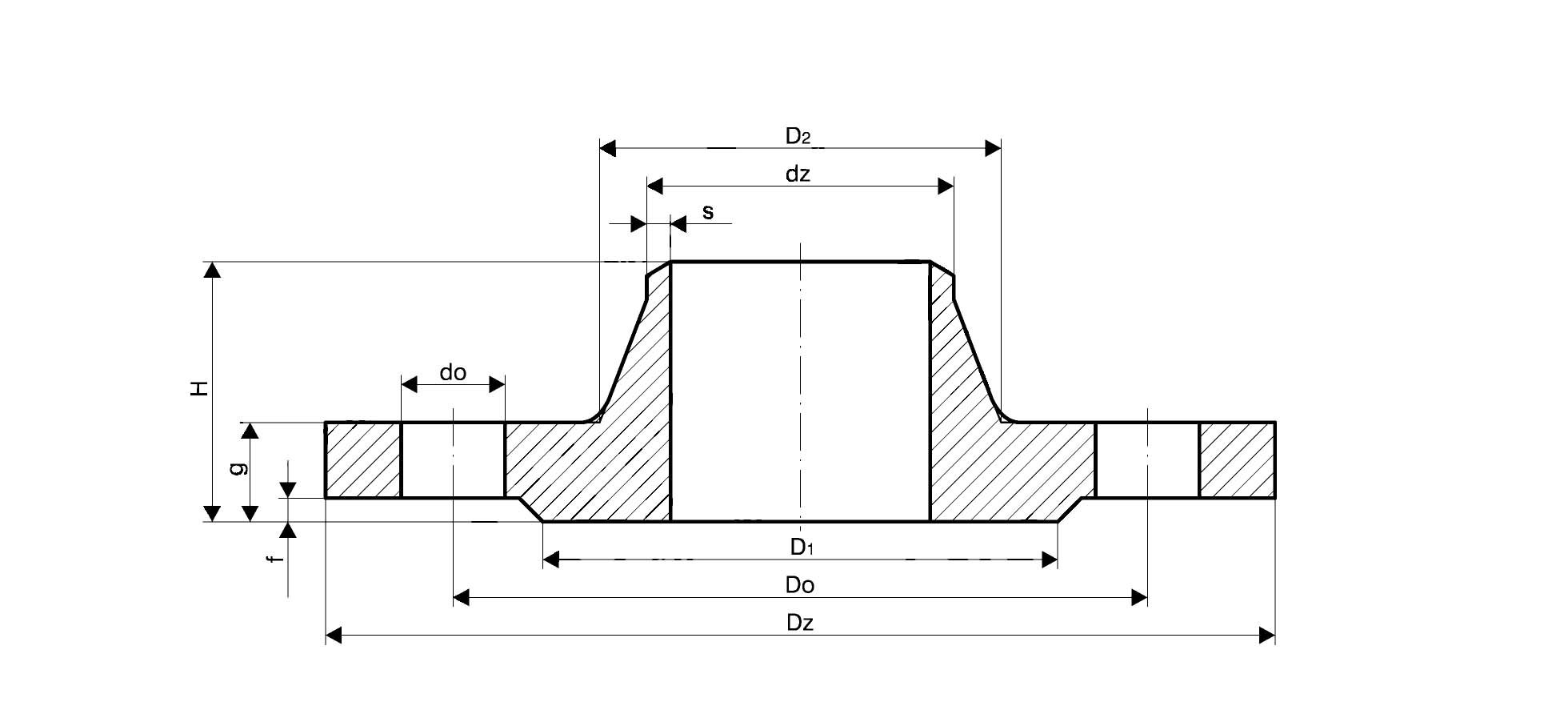

WELD NECK FLANGE ANSI B16.5 CLASS #150

Material:

steel ASTM A105WCBDimensions:

1/2" - 24"TECHNICAL DESCRIPTION

Weld neck flange ANSI B16.5 / Class # 150 are piping elements that are widely used in the construction of steel pipelines and pipe segments used in industry, shipbuilding and ship repair.

They easily differs from the flat flanges with the long cone neck, which gradually passes to a pipe or other fitting joined by a butt weld. The conical neck ensures a smooth transition to the pipe dimmer, which reduces internal material stresses. This makes them suitable for applications with high / low temperature or mechanical stresses.

The inner diameter is with size that match the internal pipe diameter, which reduce pipe corrosion and frictional wear from the passing fluid.

In stock we keep flanges ANSI B16.5 / Class # 150 and # 300, but flanges up to # 2500 can be delivered from different materials on request.

We have the necessary machining equipment, which also allows us to offer flanges with sealing surfaces.

• type of sealing surface A, B2, C, D, E, F

• non-standard sealing surfaces per job

• Profile channels for metal seals (segments) type RTJ

• Threaded flanges

• Flanges made by customer's order, and others.

MATERIALS ON STOCK</ span>

• Carbon Steel ASTM A105 WCB

</ span>

Materials

| No. | POSITION | MATERIALS | STANDART |

|---|---|---|---|

| 1 | Weld neck flange ANSI B16.5 / #150 | стомана A105 WCB (1.0432) | ASTM A 695-95 |

| other steel materials on request | |||

| ASTM A105N ; C22.8 (1.0460) | ASTM | ||

| ASTM/ASME A182 F1-F12-F11 | ASTM A 182-02 | ||

| other stainless steel materials on request | |||

| Stainless steel - ASTM A182 F304 - 304L | ASTM | ||

| Stainless steel - AISI A182 F316 - F316L | ASTM | ||

| Low temp/ alloy - ASTM A352 LF2 low temp | ASTM | ||

| High performance steel - ASTM A694 F42 ; F52 | ASTM |

Characteristics

Dimensions

| ND | Pipe O.D. | WELD NECK FLANGE ANSI B16.5 / #150 | Holes | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| dz | Dz | Do | do | H | g | d2 | S | D | f | Kg | n | |

| 1/2" | 21,3 | 88,9 | 60,5 | 15,7 | 47,8 | 11,2 | 30,2 | 2,80 | 35,1 | 1,6 | 0,48 | 4 |

| 3/4" | 26,7 | 98,6 | 69,9 | 15,7 | 52,3 | 12,7 | 38,1 | 2,95 | 42,9 | 1,6 | 0,71 | 4 |

| 1" | 33,5 | 108,0 | 79,2 | 15,7 | 55,6 | 14,2 | 49,3 | 3,40 | 50,8 | 1,6 | 1,01 | 4 |

| 1 1/4" | 42,2 | 117,3 | 88,9 | 15,7 | 57,2 | 15,7 | 58,7 | 3,55 | 63,5 | 1,6 | 1,33 | 4 |

| 1 1/2" | 48,3 | 127,0 | 98,6 | 15,7 | 62,0 | 17,5 | 65,0 | 3,70 | 73,2 | 1,6 | 1,72 | 4 |

| 2" | 60,3 | 152,4 | 120,7 | 19,1 | 63,5 | 19,1 | 77,7 | 3,95 | 91,9 | 1,6 | 2,58 | 4 |

| 2 1/2" | 73,2 | 177,8 | 139,7 | 19,1 | 69,9 | 22,4 | 90,4 | 5,25 | 104,6 | 1,6 | 4,11 | 4 |

| 3" | 88,9 | 190,5 | 152,4 | 19,1 | 69,9 | 23,9 | 108,0 | 5,45 | 127,0 | 1,6 | 4,92 | 4 |

| 3 1/2" | 101,6 | 215,9 | 177,8 | 19,1 | 71,4 | 23,9 | 122,2 | 5,70 | 139,7 | 1,6 | 6,08 | 8 |

| 4" | 114,3 | 228,6 | 190,5 | 19,1 | 76,2 | 23,9 | 134,9 | 5,95 | 157,2 | 1,6 | 6,84 | 8 |

| 5" | 141,2 | 254,0 | 215,9 | 22,4 | 88,9 | 23,9 | 163,6 | 6,95 | 185,7 | 1,6 | 8,56 | 8 |

| 6" | 168,3 | 279,4 | 241,3 | 22,4 | 88,9 | 25,4 | 192,0 | 7,10 | 215,9 | 1,6 | 10,6 | 8 |

| 8" | 219,1 | 342,9 | 298,5 | 22,4 | 101,6 | 28,4 | 246,1 | 8,25 | 269,7 | 1,6 | 17,6 | 8 |

| 10" | 273,1 | 406,4 | 362,0 | 25,4 | 101,6 | 30,4 | 304,8 | 9,30 | 323,9 | 1,6 | 24,0 | 12 |

| 12" | 323,9 | 482,6 | 431,8 | 25,4 | 114,3 | 31,8 | 365,3 | 9,55 | 381,0 | 1,6 | 36,5 | 12 |

| 14" | 355,6 | 533,4 | 476,3 | 28,4 | 127,0 | 35,1 | 400,1 | * | 412,8 | 1,6 | 48,4 | 12 |

| 16" | 406,4 | 596,9 | 539,8 | 28,4 | 127,0 | 36,6 | 457,2 | * | 469,9 | 1,6 | 60,6 | 16 |

| 18" | 457,2 | 635,0 | 577,9 | 31,8 | 139,7 | 39,6 | 505,0 | * | 533,4 | 1,6 | 68,3 | 16 |

| 20" | 508,0 | 698,5 | 635,0 | 31,8 | 144,5 | 42,9 | 558,8 | * | 584,2 | 1,6 | 84,5 | 20 |

| 24" | 609,6 | 812,8 | 749,3 | 35,1 | 152,4 | 47,8 | 663,4 | * | 692,2 | 1,6 | 115,0 | 20 |

| *) Dimension to be agreed |