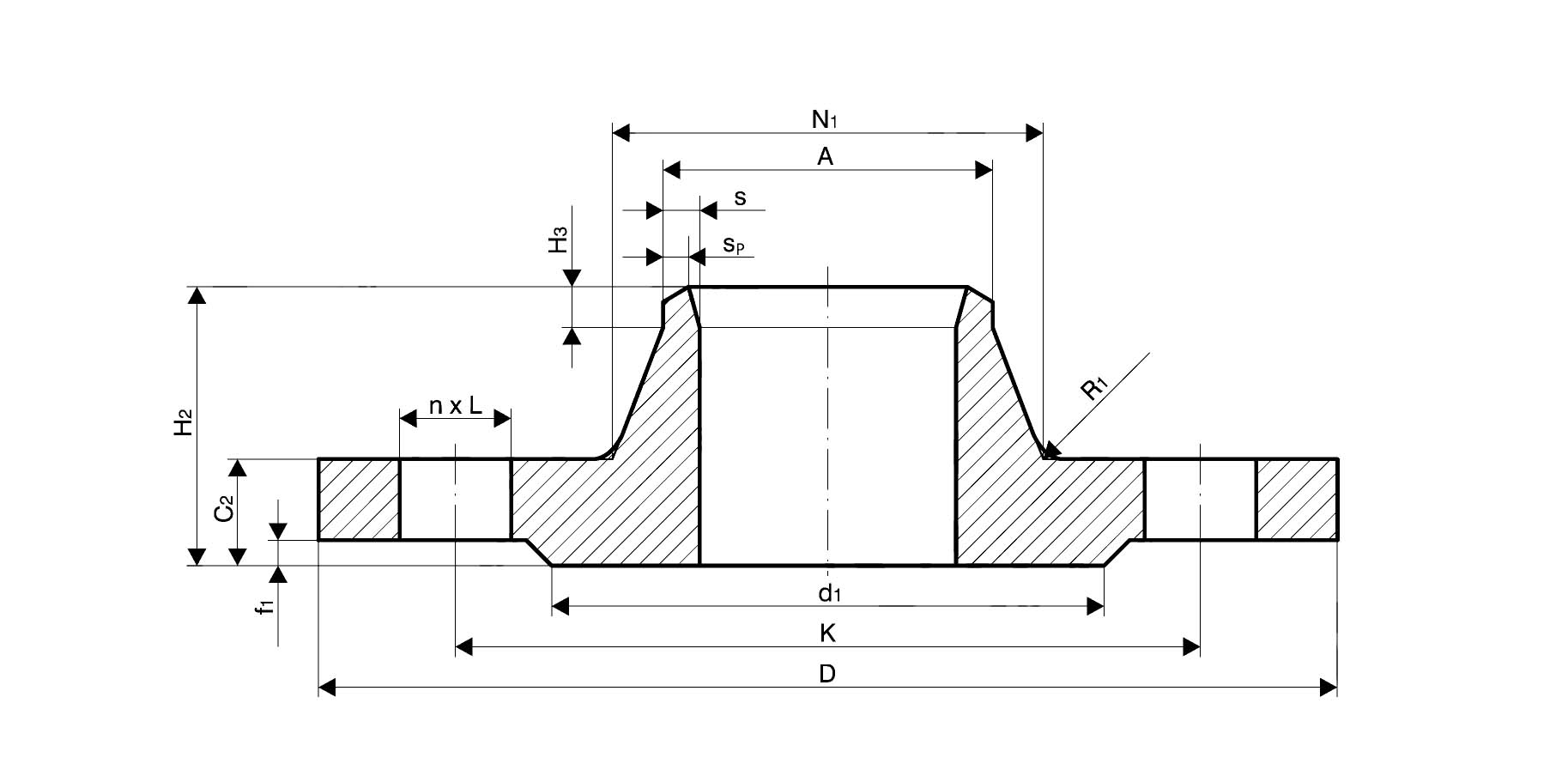

WELD NECK FLANGE TYPE 11/В1 EN1092-1 PN 40

Material:

steel EN P250GHDimensions:

DN 10 - 600TECHNICAL DESCRIPTION

Weld neck flanges according to EN1092-1 / type 11 / B1 are one of the most common used pipe connection elements and are widely used in building of steel pipelines and pipe spools for industry and repairs of many branches.

Our stock availability consists of steel flanges according to EN1092-1 type 01 / with sealing surface B1 and sizes up to DN2000. We have all necessary machine equipment, that allows us to machine flanges with different profiles and sealing surfaces as follows.

• type of sealing surface A, B2, C, D, E, F

• non-standard sealing surfaces as per clients specifivation

• machining of profile channels for metal sealing rings type RTJ

• custom machined flanges made by clients specification.

MATERIALS KEEPED ON STOCK: </ span>

• Carbon steel

P250GH (1.0460) / EN 10222-2

</ span>

Materials

| No. | PARTS | MATERIALS | STANDART |

|---|---|---|---|

| 1 | FLANGE 11/B1 EN1092-1 PN 40 | carbon steel P250GH / (1.0460) | EN 10222-2 |

| other carbon steel materials on request | |||

| P280GH / 1.0426 | EN 10222-2 | ||

| 16Mo3; 15Mo3 / 1.5415 | EN 10222-2 | ||

| other stainless steel materials on request | |||

| AISI 304L (X2CrNiMo17-12-2) / 1.4404 | EN 10222-5 | ||

| AISI 316L (X2CrNiMo17-12-2) / 1.4404 | EN 10222-5 | ||

| AISI 321 (X6CrNiTi18-10) / 1.4541 | EN 10222-5 | ||

| AISI 316Ti (X6CrNiMoTi17-12-2) / 1.4571 | EN 10222-5 |

Characteristics

Dimensions

| DN | Pipe O.D. | FLANGE TYPE 11/B1 EN1092-1 PN40 | SCREWS | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| A | D | K | L | H2 | C2 | N1 | H3 | R | s | Sp | d1 | f1 | Weight kg | n | Size | |

| 10 | 13,5* | 90 | 60 | 14 | 35 | 16 | 25 | 6 | 4 | 2 | 2 | 40 | 2 | 0,69 | 4 | M12 |

| 17,2 | 28 | 0,68 | ||||||||||||||

| 15 | 20,0* | 95 | 65 | 14 | 38 | 16 | 30 | 6 | 4 | 2 | 2 | 45 | 2 | 0,78 | 4 | M12 |

| 21,3 | 32 | 0,77 | ||||||||||||||

| 20 | 25,0* | 105 | 75 | 14 | 40 | 18 | 38 | 6 | 4 | 2,3 | 2,3 | 58 | 2 | 1,10 | 4 | M12 |

| 26,9 | 40 | 1,09 | ||||||||||||||

| 25 | 30,0* | 115 | 85 | 14 | 40 | 18 | 42 | 6 | 4 | 2,6 | 2,6 | 68 | 2 | 1,40 | 4 | M12 |

| 33,7 | 46 | 1,30 | ||||||||||||||

| 32 | 38,0* | 140 | 100 | 18 | 42 | 18 | 52 | 6 | 6 | 2,6 | 2,6 | 78 | 2 | 1,99 | 4 | M16 |

| 42,4 | 56 | 1,91 | ||||||||||||||

| 40 | 44,5* | 150 | 110 | 18 | 45 | 18 | 60 | 7 | 6 | 2,6 | 2,6 | 88 | 3 | 2,20 | 4 | M16 |

| 48,3 | 64 | 2,15 | ||||||||||||||

| 50 | 57,0* | 165 | 125 | 18 | 48 | 20 | 72 | 8 | 6 | 2,9 | 2,9 | 102 | 3 | 2,90 | 4 | M16 |

| 60,3 | 75 | 2,85 | ||||||||||||||

| 65 | 76,1 | 185 | 145 | 18 | 52 | 22 | 90 | 10 | 6 | 2,9 | 2,9 | 122 | 3 | 3,68 | 8 | M16 |

| 80 | 88.9 | 200 | 160 | 18 | 58 | 24 | 105 | 12 | 8 | 3,2 | 3.2 | 138 | 3 | 4,78 | 8 | M16 |

| 100 | 108,0* | 235 | 190 | 22 | 65 | 24 | 128 | 12 | 8 | 3,6 | 3,6 | 162 | 3 | 6,56 | 8 | M20 |

| 114,3 | 134 | 6,46 | ||||||||||||||

| 125 | 133,0* | 270 | 220 | 26 | 68 | 26 | 155 | 12 | 8 | 4 | 4 | 188 | 3 | 9,40 | 8 | M24 |

| 139,7 | 162 | 8,86 | ||||||||||||||

| 150 | 159,0* | 300 | 250 | 26 | 75 | 28 | 182 | 12 | 10 | 4,5 | 4,5 | 218 | 3 | 12,10 | 8 | M24 |

| 168,3 | 192 | 11,70 | ||||||||||||||

| 200 | 219,1 | 375 | 320 | 30 | 88 | 34 | 244 | 16 | 10 | 6,3 | 6,3 | 285 | 3 | 21,00 | 12 | M27 |

| 250 | 273,0 | 450 | 385 | 33 | 105 | 38 | 306 | 18 | 12 | 7,1 | 7,1 | 345 | 3 | 34,20 | 12 | M30 |

| _300 | 323,9 | 515 | 450 | 33 | 115 | 42 | 362 | 18 | 12 | 8 | 8 | 410 | 4 | 47,60 | 16 | M30 |

| 350 | 355,6 | 580 | 510 | 36 | 125 | 46 | 408 | 20 | 12 | 8,8 | 8,8 | 465 | 4 | 69,30 | 16 | M33 |

| 400 | 406,4 | 660 | I 585 | 39 | 135 | 50 | 462 | 20 | 12 | 11 | 11 | 535 | 4 | 98,00 | 16 | M36 |

| 450 | 457,0 | 685 | 610 | 39 | 135 | 57 | 500 | 20 | 12 | 12,5 | 12,5 | 560 | 4 | 105,00 | 20 | M36 |

| 500 | 508,0 | 755 | 670 | 42 | 140 | 57 | 562 | 20 | 12 | 14,2 | 14,2 | 615 | 4 | 130,00 | 20 | M39 |

| 600 | 610,0 | 890 | 795 | 48 | 150 | 72 | 666 | 20 | 12 | 16 | 16 | 735 | 5 | 209,00 | 20 | M45 |

| *) Pipe diameters not provided for in standard EN 1092-1: 2013 - can be made for special customer order. |