SAFETY VALVE BRONZE PROPORTIONAL THREADED HEROSE 06505

Material:

brass CW614N B 249 UNS C38500Dimensions:

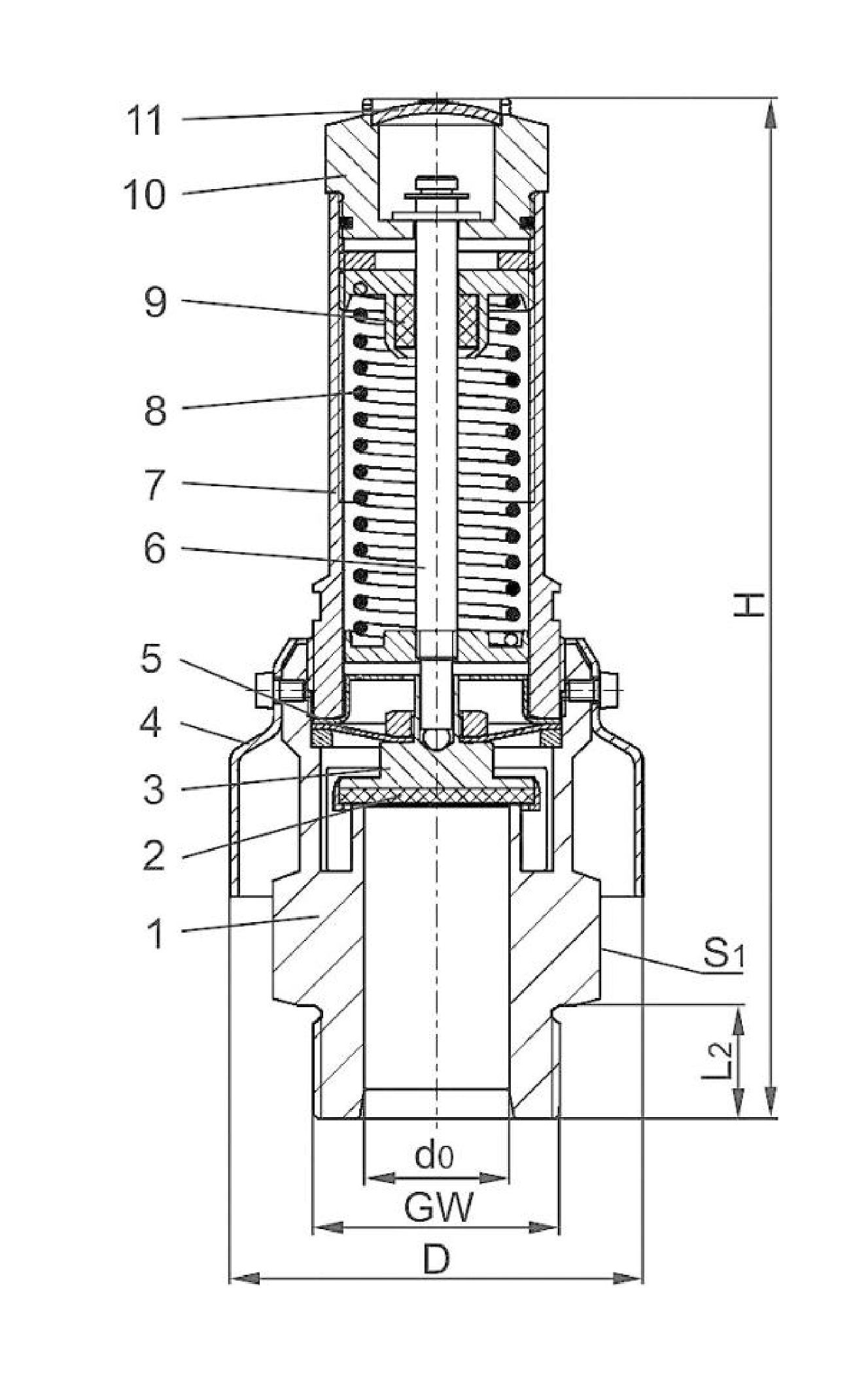

DN 12 - 2TECHNICAL DESCRIPTION

Used as a safety device for excessive pressure in gas cylinders and pressure vessels. Standard safety valve with FPM saddle seal, closed lid with unloading windows and forced opening device. Male Thread Type G (BSPP) according to ISO 228/1

PRINCIPLE OF ACTION

Automatic safety valve opening proportional to the pressure rise. The constant balance between opening pressure and closing spring responce provides a minimum flow, or minimal loss of fluid when the valve is actuated.

WORKING FLUID / ENVIRONMENT

Liquids, granulates and powders

OPTIONS

Possible options on request:

• nickel-plated outer parts

Materials

| No. | Part | Material |

|---|---|---|

| 1 | Body | CW614N B 249 UNS C38500 |

| 2 | Valve seal | FPM (Viton - GLT) |

| 3 | Disc | CW614N B 455 UNS C38500 |

| 4 | Stem | 1.4301 A 240 Grade 304 |

| 5 | Protection cap | Silicon |

| 6 | Diaphragm | CW614N B 249 UNS C38500 |

| 7 | Stem | CW614N B 249 UNS C38500 |

| 8 | Bonnet | 1.4571 A 313 Grade 316 Ti |

| 9 | Spring | PTFE |

| 10 | Lifting device | CW614N B 249 UNS C38500 |

| 11 | Closing Cap | CW507L B 36 UNS C26800 |

Characteristics

Dimensions

| DN | Orifice | Dim. Code | Setup range | Protection cap dia. | Spanner | Weight kg | Discharge coeff. at 3 Bar | Discharge coeff. at 3.5 Bar | Discharge coeff. at 4.5 Bar | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| GW | d₀ | .X. | Bar | H | L₂ | S₁ | kg | aᵥᵥ | aᵥᵥ | aᵥᵥ | |

| 1" | 24 | 1000 | 0.5-0.6 | 194 | 18 | 80 | 55 | 1.75 | 0.62 | 0.57 | |

| 1 1/4" | 28 | 2812 | 0.5-4.5 | 198 | 22 | 80 | 55 | 1.85 | 0.58 | ||

| 1 1/2" | 28 | 2814 | 0.5-4.5 | 198 | 22 | 80 | 55 | 1.9 | 0.58 | ||

| 1 1/4" | 31 | 3112 | 0.5-0.6 | 191 | 22 | 80 | 55 | 2 | 0.68 | 0.65 | |

| 1 1/2" | 31 | 3114 | 0.5-0.6 | 191 | 22 | 80 | 55 | 2.3 | 0.68 | 0.65 | |

| 2" | 48 | 2000 | 0.5-3.5 | 232 | 25 | 115 | 85 | 4.5 | 0.52 |

Capacity

| DISCHARGE CAPACITY | |||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| P set | GW: | 1 | 1-1/4 | 1-1/2 | 1-1/4 | 1-1/2 | 2 | ||||||

| bar (g) | d₀ (mm): | 24.0 | 28.0 | 28.0 | 31.0 | 31.0 | 48.0 | ||||||

| A₀ (mm²): | 452.4 | 615.8 | 615.8 | 754.8 | 754.8 | 1810.0 | |||||||

| Media: | air in m³/h at 0 °C and 1013.25 mbar | ||||||||||||

| 0.5 | 237 | 297 | 297 | 435 | 435 | 835 | |||||||

| 0.6 | 268 | 326 | 326 | 482 | 482 | 949 | |||||||

| 0.7 | 299 | 354 | 354 | 535 | 535 | 1063 | |||||||

| 0.8 | 329 | 392 | 392 | 579 | 579 | 1153 | |||||||

| 0.9 | 353 | 422 | 422 | 631 | 631 | 1240 | |||||||

| 1.0 | 372 | 449 | 449 | 673 | 673 | 1250 | |||||||

| 1.2 | 414 | 508 | 508 | 759 | 759 | 1390 | |||||||

| 1.4 | 456 | 578 | 578 | 848 | 848 | 1531 | |||||||

| 1.6 | 504 | 639 | 639 | 941 | 941 | 1675 | |||||||

| 1.8 | 553 | 703 | 703 | 1031 | 1031 | 1863 | |||||||

| 2.0 | 604 | 768 | 768 | 1123 | 1123 | 2059 | |||||||

| 2.2 | 648 | 825 | 825 | 1200 | 1200 | 2243 | |||||||

| 2.4 | 694 | 883 | 883 | 1277 | 1277 | 2431 | |||||||

| 2.6 | 740 | 942 | 942 | 1354 | 1354 | 2546 | |||||||

| 2.8 | 782 | 995 | 995 | 1431 | 1431 | 2657 | |||||||

| 3.0 | 825 | 1051 | 1051 | 1511 | 1511 | 2770 | |||||||

| 3.2 | 868 | 1105 | 1105 | 1588 | 1588 | 3024 | |||||||

| 3.4 | 910 | 1158 | 1158 | 1665 | 1665 | 3170 | |||||||

| 3.5 | 931 | 1185 | 1185 | 1628 | 1628 | 3244 | |||||||

| 3.6 | 952 | 1212 | 1212 | 1665 | 1665 | - | |||||||

| 3.8 | 994 | 1266 | 1266 | 1739 | 1739 | - | |||||||

| 4.0 | 1036 | 1319 | 1319 | 1812 | 1812 | - | |||||||

| 4.2 | 1078 | 1373 | 1373 | 1886 | 1886 | - | |||||||

| 4.4 | 1120 | 1427 | 1427 | 1960 | 1960 | - | |||||||

| 4.5 | 1049 | 1453 | 1453 | 1997 | 1997 | - | |||||||

| 4.6 | 1069 | - | - | 2034 | 2034 | - | |||||||

| 4.8 | 1107 | - | - | 2107 | 2107 | - | |||||||

| 5.0 | 1148 | - | - | 2185 | 2185 | - | |||||||

| 5.2 | 1187 | - | - | 2259 | 2259 | - | |||||||

| 5.4 | 1226 | - | - | 2333 | 2333 | - | |||||||

| 5.6 | 1265 | - | - | 2407 | 2407 | - | |||||||

| 5.8 | 1304 | - | - | 2481 | 2481 | - | |||||||

| 6.0 | 1343 | - | - | 2555 | 2555 | - | |||||||

| Discharge capacity is measured at fully open valve. |